National free service hotline£º400-879-6552

Add to Favorites??|??Set to the home page ??|??Sitemap??|??Contact

National free service hotline£º400-879-6552

Add to Favorites??|??Set to the home page ??|??Sitemap??|??Contact

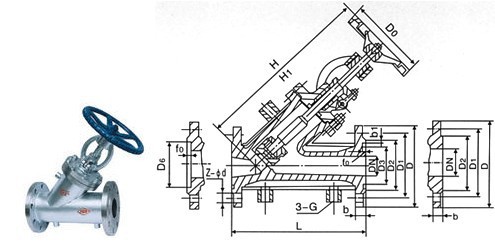

Insulation stop valve

³¢´Ç³¦²¹³Ù¾±´Ç²Ô£ºHome > Insulation stop valve

Stainless steel valve BJ45W cut-off valve structure features are as follows:

Plug valve cover, rod support and lift stem metal seal.

BJ45W valve body and valve cover connection form

Class150~Class900 uses the plug valve cover; Class1500~Class2500 uses the self pressure seal valve cover.

BJ45W valve cover gasket type

Class150~Class300 valve with stainless steel graphite spiral wound gasket; Class600 valve can be made of stainless steel graphite spiral wound gasket can be used metal ring gasket; Class900 valve can be used metal ring gasket, Class1500~Class2500 valve with self sealing ring.

BJ45W operating mode of thermal insulation stop valve

Under normal circumstances, the use of hand wheel, impact hand wheel or gear transmission mode, according to the user needs to use sprocket drive or electric drive.

Insulation stop valve BJ45W packing seal

Generally, it is used as filler material, and can provide PTFE or composite filler material according to user's requirement. Packing and stuffing the contact surface roughness of 3.2 m, can guarantee the stem and packing contact surface bonded but is free to rotate through the precision machining of the valve stem sealing surface roughness of 0.8 m can ensure reliable sealing valve.

Spring loaded packing impact system

If the customer needs, can be used to fill the spring packing shock system to provide the durability and reliability of packing seal.

Upper seal seat design

All the valves provided by our company have reverse seal design. Under normal circumstances, carbon steel globe valve seat design uses a separate inverted seal structure, the stainless steel valve sealing when the direct processing or welding process. When the valve in the fully open position, the sealing surface is very reliable. Although according to the standard API600 has a reverse seal, but this is not used as a basis for replacement of packing in the case of pressure.

valve seat

Carbon steel valve seat is usually used forged steel material, the sealing surface of the valve seat according to customer requirements for spray welding alloy, NPS is less than 10''valve using a split threaded into the valve seat, if the user needs the welding seat structure may also be provided; NPS = 12 valve seat structure by welding; stainless steel valve seat is generally used integral or in body welding hard alloy after direct machining of valve seat. If the user needs, stainless steel valve seat can also be used in the separation of screw thread and welded seat structure.

Stem design

The whole forging process is adopted, and the minimum diameter is determined according to the standard requirements.

Stem nut

Under normal circumstances, the stem nut material using ASTM A439D2. According to the materials with copper alloy such as user requirements, the valve of large diameter (NPS = 10''Class150; NPS = 8''Class300; NPS = 6''Class600; NPS = 5''Class900), stem nut and stem bracket design of rolling bearings, can effectively reduce the torque of the valve opening closing valve can easily switch.

Special stop valve

First, BJ45H/W angle insulation valve overview:

The valve is suitable for chemical industry, chemical fertilizer industry pipeline, the jacket into the steam can prevent the crystallization of the media.

Two, BJ45H/W angle type stop valve structure:

Three, BJ45H/W angle insulation valve design standards:

Design and manufacture: GB12233

Flange size: JB/T79 GB9113

Structure length: GB12221

Inspection and testing: GB/T13927

Four, BJ45H/W angle insulation valve performance specification:

ÐͺŠ| ¹«³ÆѹÁ¦ | ÊÔÑéѹÁ¦ | ÊÊÓÃÎÂ¶È | ÊÊÓýéÖÊ | ±£ÎÂÌ×ѹÁ¦ | |

Shell | Seal | |||||

BJ45W-25P | 2.5 | 3.75 | 2.75 | ¡Ü200 | Acetic urea | ¡Ü1.3 |

BJ45W-40P | 4.0 | 6.0 | 4.4 | |||

BJ45W-64P | 6.4 | 9.0 | 6.6 | Acetic urea | ||

BJ45W-25P | 2.5 | 3.75 | 2.75 | |||

BJ45W-40P | 4.0 | 6.0 | 4.4 | |||

BJ45W-64P | 6.4 | 9.0 | 6.6 | |||

Five, BJ45H/W angle insulation valve main parts material:

Áã¼þÃû³Æ³¢°Õ·¡²Ñ | ´Ü³Ò1°ä¸é18±·±õ9°Õ±õϵÁÐ | ´Ü³Ò°¿°¿°ä¸é18±·±õ10ϵÁÐ | ´Ü³Ò1°ä°ù18±·¾±12²Ñ°¿2°Õ¾±ÏµÁÐ | ´Ü³Ò°¿°¿°ä¸é17±·±õ14²Ñ°¿2ϵÁÐ | °Â°äµþϵÁÐ |

·§Ìå/·§¸ÇÊÀµþ°¿¶Ù³Û/°ä´¡±Ê | ZG1CR18NI9TI | ZGOOCR18NI10 | ZG1Cr18Ni12MO2Ti | ZGOOCR17NI14MO2 | WCB |

Õ¢°å°Â·¡¶Ù³Ò·¡ | ZG1CR18NI9TI | ZGOOCR18NI10 | ZG1Cr18Ni12MO2Ti | ZGOOCR17NI14MO2 | 1Cr13 |

·§¸Ë³§°Õ·¡²Ñ | 1CR18NI9TI | 00cr18ni10 | 1CR18NI12MOTI | OOCR17NI14MO | 1Cr13 |

ÌîÁϱʴ¡°ä°±õ±·³Ò | ±Ê°Õ¹ó·¡·ÄÖ¯ | ±Ê°Õ¹ó·¡·ÄÖ¯ | ±Ê°Õ¹ó·¡·ÄÖ¯ | ±Ê°Õ¹ó·¡·ÄÖ¯ | ʯī |

µæƬ³Ò´¡³§°·¡°Õ | 304L+PTFE | 304L+PTFE | 316L+PTFE | 316L+PTFE | ʯī+304 |

ѹ¸ÇGLAND FLANGE | ZG1CR18NI9TI | ZG00CR18ni10 | ZG1Cr18Ni12MO2Ti | ZGOOCR17NI14MO2 | WCB |

ÌîÁÏѹ»· | 1CR18NI9TI | 00CR18NI10 | 1Cr18NI12MOTI | OOCR17NI14MO | 1Cr13 |

ÂÝ˨µþ°¿³¢°Õ | 1cr17ni2 | 1CR17NI2 | 1Cr17NI2 | 1Cr17Ni2 | 35CrMoA |

ÂÝĸ±·±«°Õ | 1cr18ni9ti | 1CR18NI9TI | 1Cr18NI9ti | 1Cr18NI9ti | 45 |

GB 2.5MPa | |||||||||||

DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

L | 170 | 190 | 210 | 230 | 260 | 300 | 340 | 380 | 430 | - | 550 |

H | 260 | 310 | 375 | 375 | 385 | 450 | 485 | 600 | 625 | 735 | 790 |

D0 | 120 | 140 | 160 | 160 | 160 | 240 | 240 | 280 | 320 | 360 | 360 |

GB 4.0MPa | |||||||||||

DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

L | 170 | 190 | 210 | 230 | 260 | 300 | 340 | 380 | 430 | - | 550 |

H | 260 | 310 | 375 | 375 | 385 | 450 | 485 | 600 | 625 | 735 | 790 |

D0 | 120 | 140 | 160 | 160 | 160 | 240 | 240 | 280 | 320 | 360 | 360 |

GB 6.4MPa | |||||||||||

DN | 25 | 32 | 50 | 65 | 100 | 150 | |||||

L | 235 | 260 | 300 | 340 | 430 | 415 | |||||

H | 375 | 385 | 450 | 510 | 670 | 670 | |||||

D0 | 160 | 160 | 240 | 240 | 400 | 400 | |||||

Mobile site

App